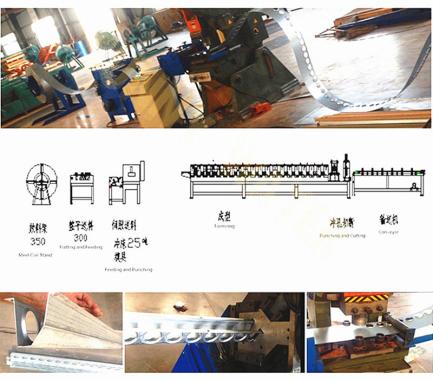

Category Solar Machinery | Tag Industry

Application:

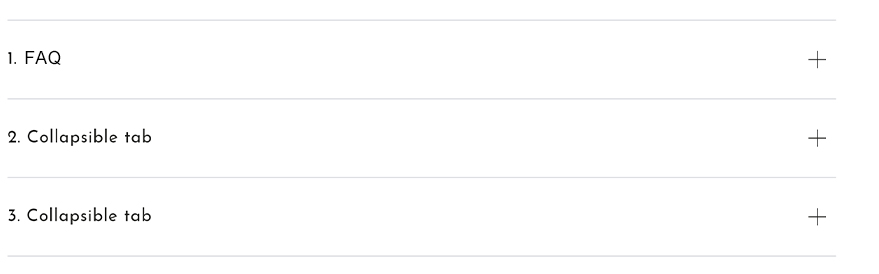

![]() Solar Water Heater Support Frame front & back leg automatic forming, punching and cutting.

Solar Water Heater Support Frame front & back leg automatic forming, punching and cutting.

Product Description

One time punching holes and forming. Operation only required entry the material to the pipe line. All molding rollers adopt the material of Gr12 high hardness steel. After 810 centigrade high temperature oil quenching heat treatment, ensure the wear resistance of the mold. Greatly improve the service life of molding rollers. Forming width and shape can be customized.

Equip with 4 sets punching molds, 1 set parallel cutting mold, 2 sets left & right diagonal cutting molds. Front & back leg, left & right leg cutting no need mold change, can be auto control.

TECHNICAL PARAMETERS

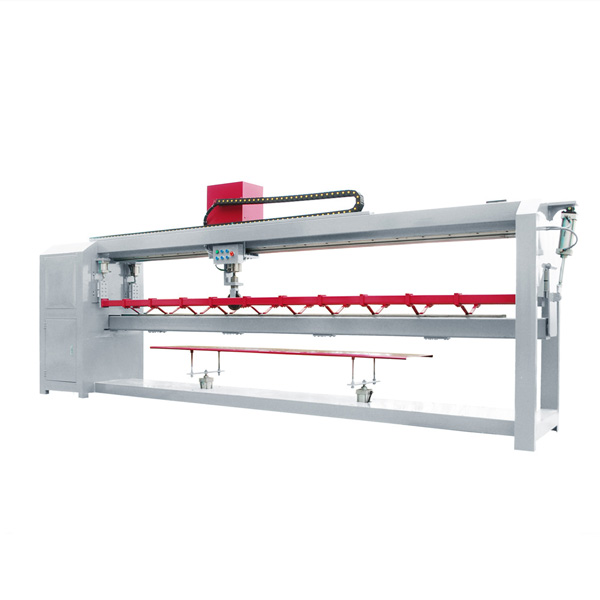

Production Picture

Related Products

Optional accessories

Product Details:

Product Description

One time punching holes and forming. Operation only required entry the material to the pipe line. All molding rollers adopt the material of Gr12 high hardness steel. After 810 centigrade high temperature oil quenching heat treatment, ensure the wear resistance of the mold. Greatly improve the service life of molding rollers. Forming width and shape can be customized.

Equip with 4 sets punching molds, 1 set parallel cutting mold, 2 sets left & right diagonal cutting molds. Front & back leg, left & right leg cutting no need mold change, can be auto control.

TECHNICAL PARAMETERS

Production Picture

About Us

In the belief of environmental protection, our company develops various products related to solar energy resources in order to make contributions to environmental protection.

We hope that in the future there will be a people-oriented, energy and environment develop together society.

+86 18652546893

+86 18652546893

+86 18652546893

+86 18652546893